Rockfall Protection Nets

Rockfall Netting is wire mesh netting which is used to prevent rocks from falling onto the road, railways and other structures. The mesh is made of galvanized or PVC coated double twisted steel woven wire in acc.with STM A641and EN10223-3. Due to the unravelling character of double twist, the mesh can withstand huge forces and will not unravel even if a wire is broken. Rockfall protection netting with a PVC coating can be used in aggressive environments. In addition to galvanization, the steel wire is coated with a PVC layer of a nominal thickness of 0.50 mm. The technical characteristics and the resistance of the PVC to aging meet the relevant standards.

Mild Steel Wire

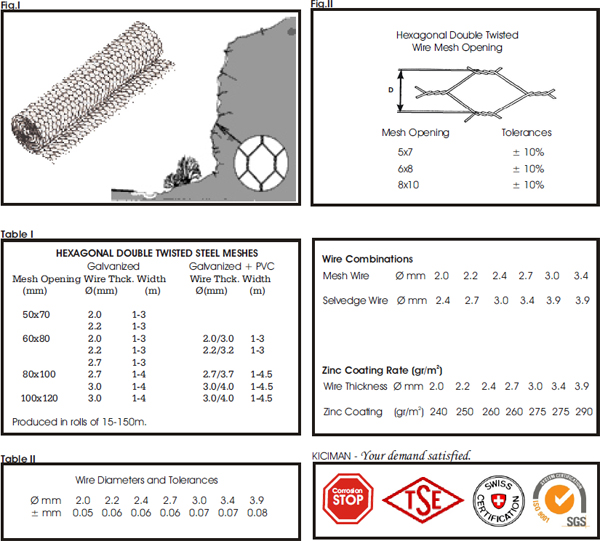

All the wires used in rockfall nets and lacing wire have the tensile strength of 2 38-48kg/mm (54,000-70,000psi) acc.to BS1052/80 and ASTM A641-97. (The figures below are of the wire prior to manufacturing mesh). The tolerances on diameter of zinc coated wire in Table II. The elongation at break is min.12% and test to be carried out on a sample of minimum 30cm (12 in.) long, before manufacturing the mesh. (In accordance with ASTM A370-92) Galvanisation strictly conforms to ASTM A641-97 Class III Soft Temper Coating. Zinc adherence has to be such that when thewire is wrapped around a cylindrical mandrel having 4 times the diameter of the wire, the zinc shall not flake or crack to such an extent that any flake or crack can be removed by simply rubbing with bare fingers.

Steel Grid

Rockfall Netting is wire mesh netting which is used to prevent rocks from falling onto the road, railways and other structures. The mesh is made of galvanized or PVC coated double twisted steel woven wire in acc.with STM A641and EN10223-3. Due to the unravelling character of double twist, the mesh can withstand huge forces and will not unravel even if a wire is broken. Rockfall protection netting with a PVC coating can be used in aggressive environments. In addition to galvanization, the steel wire is coated with a PVC layer of a nominal thickness of 0.50 mm. The technical characteristics and the resistance of the PVC to aging meet the relevant standards. Mild Steel WireAll the wires used in rockfall nets and lacing wire have the tensile strength of 2 38-48kg/mm (54,000-70,000psi) acc.to BS1052/80 and ASTM A641-97. (The figures below are of the wire prior to manufacturing mesh). The tolerances on diameter of zinc coated wire in Table II. The elongation at break is min.12% and test to be carried out on a sample of minimum 30cm (12 in.) long, before manufacturing the mesh. (In accordance with ASTM A370-92) Galvanisation strictly conforms to ASTM A641-97 Class III Soft Temper Coating. Zinc adherence has to be such that when thewire is wrapped around a cylindrical mandrel having 4 times the diameter of the wire, the zinc shall not flake or crack to such an extent that any flake or crack can be removed by simply rubbing with bare fingers.

Mustafa Kemal Mah. Dumlupınar Blv. Tepe Prime İş Mr. A Blok Kat:12 No:73 Ankara/Turkey - T: +90 (312) 212 96 35 - F: +90 (312) 212 96 36 - kiciman@kiciman.com